I finished this recently and thought some of you might like to see.

Finished picture first:

So, earlier last year I picker up a couple of DE10 Nanos. I originally ordered a RMC MiSTer Multisystem to put one of them in but after hearing cools thoughts on the one he bought I cancelled the order. cools then found the [MiSTer Mini-ITX Ironclad Plus] which is basically a Mini ITX form factor IO board. This looked to fit the bill much better and so I picked one up too.

Looking back I ordered the Ironclad at the start of March last year However I didn't actually receive it until September so I guess four months isn't too bad to complete a project once I had received the main parts, certainly better than 10 months I guess!

However I didn't actually receive it until September so I guess four months isn't too bad to complete a project once I had received the main parts, certainly better than 10 months I guess!

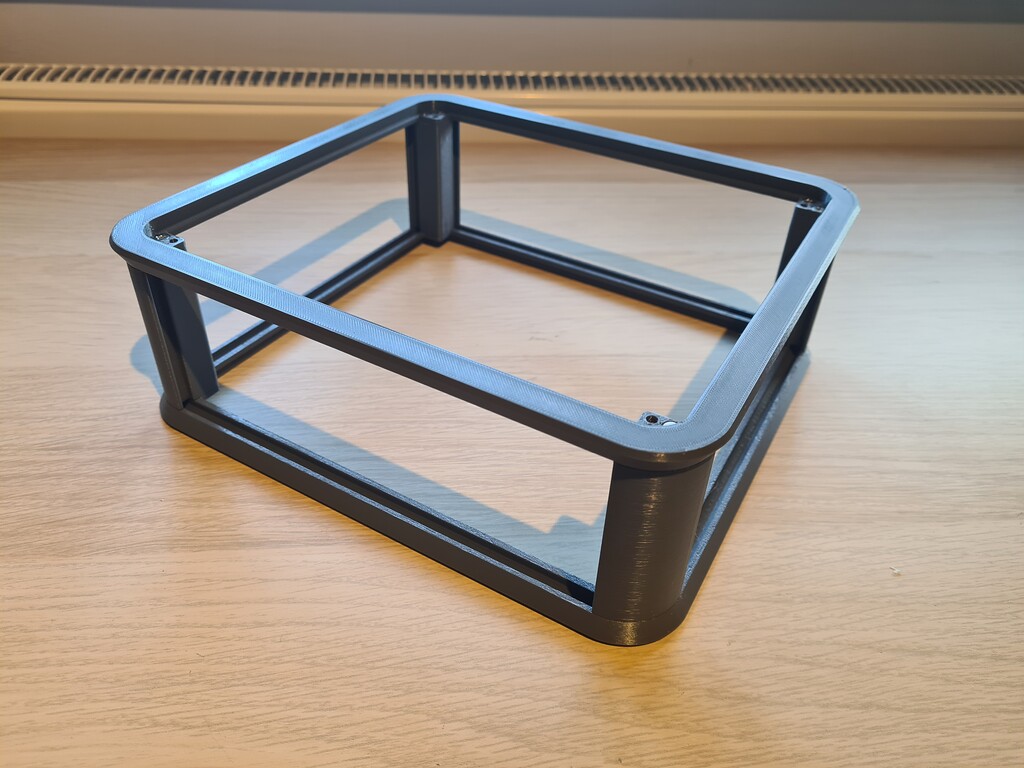

I was looking for a Mini ITX case for it and coudn't really find anything to suit my needs exactly and thought it might be fun to try and make something. I couldn't do too much until I actually received the Ironclad board but I started to mock up what it might look like. This was a bit of very early development:

View: https://youtu.be/ICiLlHDbLjM

The ITX mobo, SSD, USBs and button are just some random .stp's I found online to get started.

The plan was a 3D printed frame with a mixture of printed panels and tinted acrylic for the top, front and bottom. I wanted to see if I could fit and mount a SSD in under the Ironclad and I planned on adding a couple of USB ports on the front and a LED ring power button.

That's most of the spiel done. I did take a fair few more pictures whilst working on lots of the parts. If I get time and there is any interest I will upload them along with some notes. Otherwise most of these pictures are of final assembly.

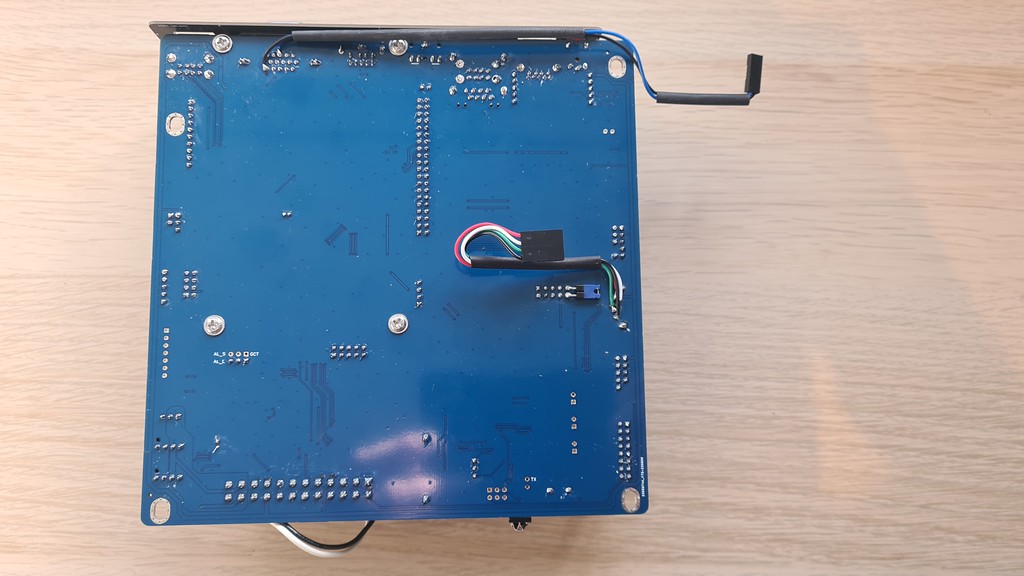

Ironclad mobo the day I received it and sat on one of my 3D printer sheets. As you can see it just fits with room around it to print the frame:

Printing the corner pieces:

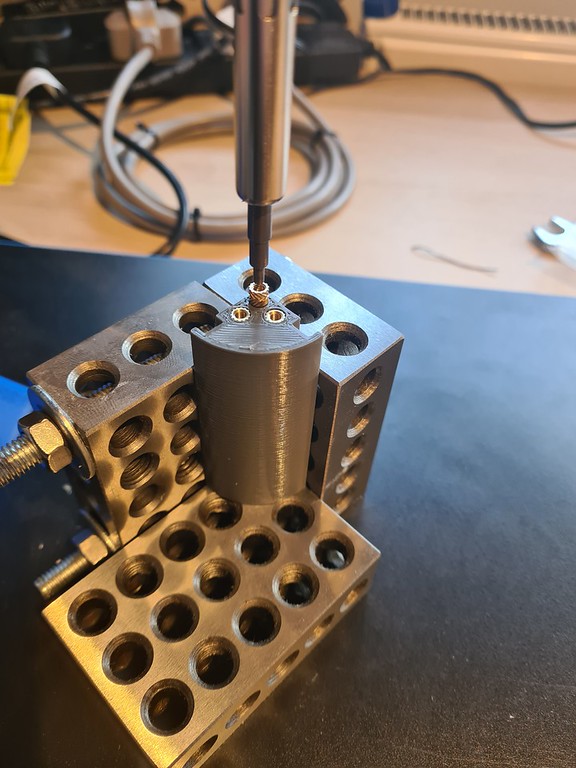

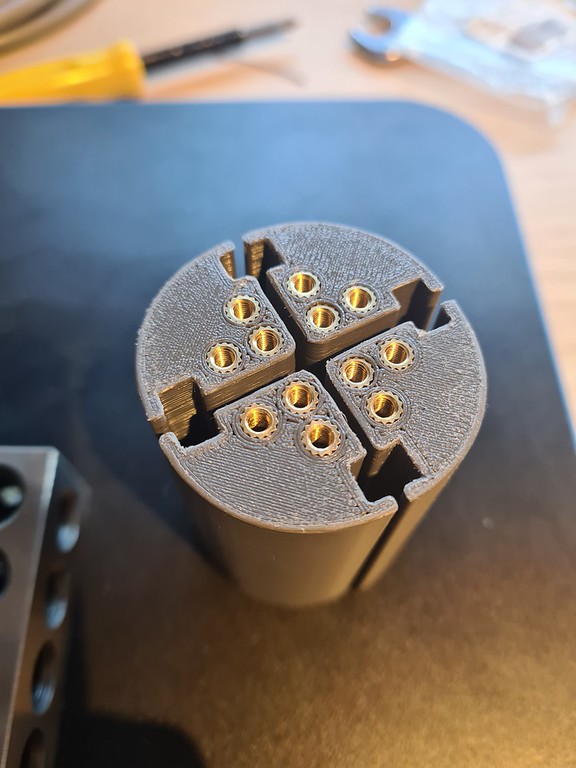

I had previously built a press for inserting threaded brass inserts. I actually built it with this project in mind as I knew I would have loads to insert and they all needed to be perpendicular to the printed parts:

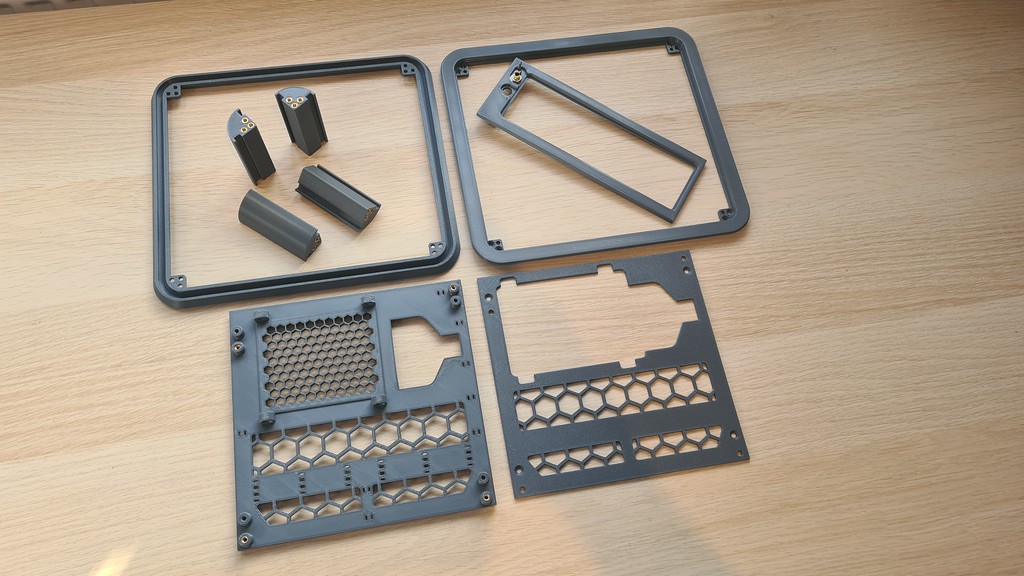

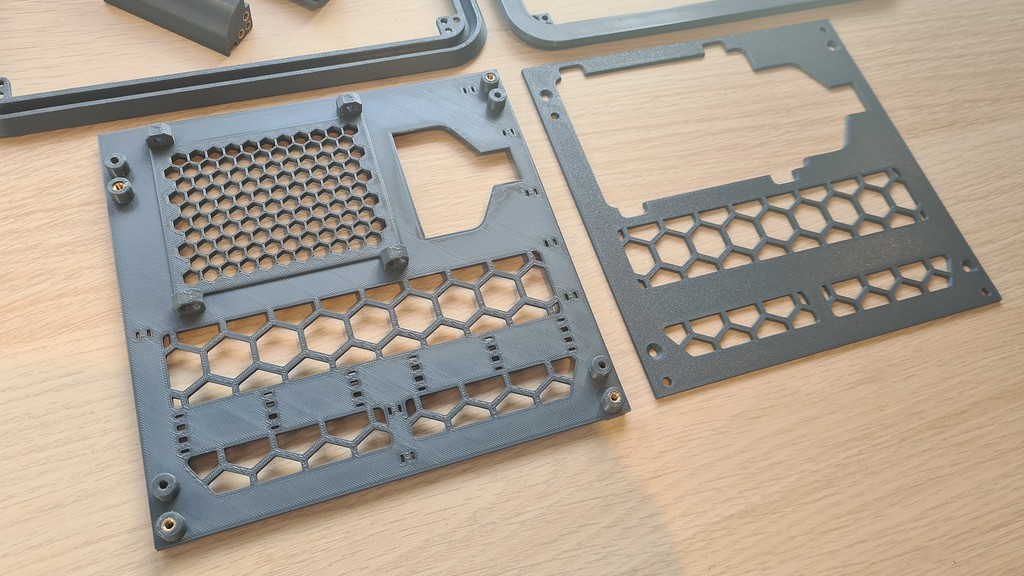

A load of other parts printed:

Assembled:

Acrylic top and bottom panels. These were made on my router table and hand polished:

Front panel. Once again made on my router table. I've got lots more info on these steps I can post later. I used some 2m USB extensions for the USB ports:

Side panels. I originally printed the two left hand panels. Just before Christmas I visited a laser manufacturer and had access to a machine for the afternoon so I cut the panels on the right. The whole design is fairly modular so the panels can be swapped out fairly easily:

I had some issues with the MiSTer stickers curling up at the corners. I managed to make them adhere a little better using some 3M spray mount but they're still not perfect and I'm trying to source some better ones.

1TB SSD with a SATA>USB cable that I cut off and added a pin header connector to:

Top removed and side panels added. These pictures are with the 3D printed side panels. I swapped them out for the laser cut ones later. I fitted a PWM fan to the LHS side. There are PWM fan headers on the Ironclad and there is a temperature sensor under the DE10 so the fans will run at the minimum speed required to keep the DE10 cool:

I made a couple of mods to the underside of the Ironclad. I added a jumper to bridge two pins for use with adding a I2S DAC to the top side of the motherboard. As I was mounting the SSD under the mobo I added a connector to the USB through holes rather than run a cable from the top side to the bottom. I also tapped composite sync at the top of the board so I can add a composite sync phono jack for use with Guncons:

I'm limited to 20 pictures in a post so I'll continue below...

Finished picture first:

So, earlier last year I picker up a couple of DE10 Nanos. I originally ordered a RMC MiSTer Multisystem to put one of them in but after hearing cools thoughts on the one he bought I cancelled the order. cools then found the [MiSTer Mini-ITX Ironclad Plus] which is basically a Mini ITX form factor IO board. This looked to fit the bill much better and so I picked one up too.

Looking back I ordered the Ironclad at the start of March last year

I was looking for a Mini ITX case for it and coudn't really find anything to suit my needs exactly and thought it might be fun to try and make something. I couldn't do too much until I actually received the Ironclad board but I started to mock up what it might look like. This was a bit of very early development:

The ITX mobo, SSD, USBs and button are just some random .stp's I found online to get started.

The plan was a 3D printed frame with a mixture of printed panels and tinted acrylic for the top, front and bottom. I wanted to see if I could fit and mount a SSD in under the Ironclad and I planned on adding a couple of USB ports on the front and a LED ring power button.

That's most of the spiel done. I did take a fair few more pictures whilst working on lots of the parts. If I get time and there is any interest I will upload them along with some notes. Otherwise most of these pictures are of final assembly.

Ironclad mobo the day I received it and sat on one of my 3D printer sheets. As you can see it just fits with room around it to print the frame:

Printing the corner pieces:

I had previously built a press for inserting threaded brass inserts. I actually built it with this project in mind as I knew I would have loads to insert and they all needed to be perpendicular to the printed parts:

A load of other parts printed:

Assembled:

Acrylic top and bottom panels. These were made on my router table and hand polished:

Front panel. Once again made on my router table. I've got lots more info on these steps I can post later. I used some 2m USB extensions for the USB ports:

Side panels. I originally printed the two left hand panels. Just before Christmas I visited a laser manufacturer and had access to a machine for the afternoon so I cut the panels on the right. The whole design is fairly modular so the panels can be swapped out fairly easily:

I had some issues with the MiSTer stickers curling up at the corners. I managed to make them adhere a little better using some 3M spray mount but they're still not perfect and I'm trying to source some better ones.

1TB SSD with a SATA>USB cable that I cut off and added a pin header connector to:

Top removed and side panels added. These pictures are with the 3D printed side panels. I swapped them out for the laser cut ones later. I fitted a PWM fan to the LHS side. There are PWM fan headers on the Ironclad and there is a temperature sensor under the DE10 so the fans will run at the minimum speed required to keep the DE10 cool:

I made a couple of mods to the underside of the Ironclad. I added a jumper to bridge two pins for use with adding a I2S DAC to the top side of the motherboard. As I was mounting the SSD under the mobo I added a connector to the USB through holes rather than run a cable from the top side to the bottom. I also tapped composite sync at the top of the board so I can add a composite sync phono jack for use with Guncons:

I'm limited to 20 pictures in a post so I'll continue below...

Last edited: